Business Areas

Laser Technology

Eliminate rework in High-precision measurement processes

High Precision Measurements Technics, capable of producing measurements with high reliability levels will only make your business achieve a potential increase in operating times, and a potential decrease in downtime. The most common laser technology applications are:

An exceptional precision measurement technology, requiring 30 to 80 % less time, compared to conventional methods.

Covering spaces up to 300 meters @2 mm (984 ft @ 0,080 in), The 3D Scanner will allow you to gather complex field as-build data effortless. (i.e, pipe layouts, foundations, elevations, etc.)

Measuring ranges up to 80 meters with 0.009 mm precision (262 ft – 0.00035”), the Laser Tracker a key performer into decreasing intervention time and rework.

Mechanical Joints Integrity

You can reach THE ZERO LEAKAGE goal.

Actively working on securing the integrity of bolted mechanical joints, through a wide range of actions.

ASME PCC-1, EN 1591 Theoretical and Hands-on Training, making sure your personnel is properly qualified.

Atlas Copco Industrial Technology is available to your team. With the leading technology and state of the art tools that only experts can give you.

Controlled load application techniques (torque or tensioning) and ultrasound bolt’s elongation testing. Cronic Failure analysis. Taylor made designed management system for your couplings systems. This will only incur to the maximum potential growth value for your business.

Based on ASME PCC-1 appendices, finite elements, simulations Lower probability of emergency stops, Higher availability.

Aiming for:

Less probability of leaks or containment capacity loss, decreasing emergency stops.

We provide the appropriate standardized training for your specific needs, making sure your personnel is properly qualified. Lower accidents rate, higher productivity and, less execution time are achievable.

On-site Machining

Recovering your assets performance of in a long-lasting way.

AT group, makes on-site machining processes available to you. Recovering the functions or dimensions associated with major components is possible with our portable milling, in accordance with the ASME PCC-2 guidelines. This alternative bypasses high dimension equipment’s extraction or disassembly using portable machining equipment to return their assets to optimal conditions. AT has the equipment, talent, and technology to meet your requirements.The most frequent applications:

¾ to 140 inches in Mounting ranges.

Less chance of rework, less intervention time.

Machine tools accuracy inspection.

Results Verification.

Higher productivity, less downtime.

Mounting ranges up to 78 inches.

Less chance of reworking, Less intervention time.

Assets Health

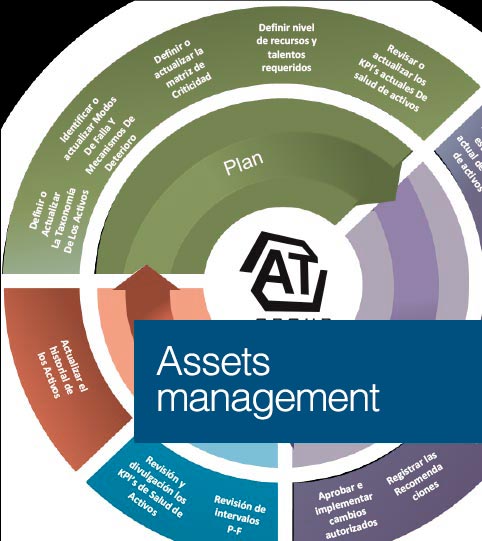

Support in the continuous improvement cycle to get higher assets' performance

AT Group, has the ability to provide integrated solutions in mutual technical collaboration with Emerson Process Management, ranging from the provision of technology to the execution of specific services. Under a Continuous Improvement methodology approach, Monitoring key specific variables on deterioration and applying non-invasive tests, AT Group, can provide you with a smooth transition in your automation processes. Performance Critical Equipment Monitoring based on (RCM, FMEA, RCA) is possible while reviewing, assessing, installing and implementing permanent wireless monitoring systems.

The focus is always fixed on the continuous improvement of every asset’s performance.

Vibration analysis.

Oil Analysis

Thermography

Continuous improvement certified staff, make possible achieving your goals.

We are a Company heavily invested in technology, innovation, and expertise to contribute to the improvement of assets’ performance, 24 Hours / 7 days a week, 365 days a year, under strict safety standards. We offer a series of specialized solutions developed by our highly trained talented team.

LINKS

Colombia

Bogota

![]()

Venezuela

Anzoategui / Falcon

![]()

United States

Florida

![]()

© 2019 – The AT Group – All rights reserved

Created by Pineapple Marketing